Metal Roofing Options (Repair & Installation) in Washington DC

Metal roofs are becoming a popular choice for homeowners in Washington, DC. They offer many benefits, including durability, energy efficiency, and long-lasting protection. At Washington DC Roofing Company, we offer a range of metal roofing options to suit different needs and budgets.

We provide expert metal roof installation and repair services for residential and commercial properties in the DC area. Our team of skilled roofers can help you choose the best metal roofing material for your home or business. Some common options include standing seam, corrugated panels, and metal shingles.

Types of Metal Roofing Systems Offered by Washington DC Roofing Company

We offer a range of metal roofing options to suit different architectural styles and homeowner needs. Our systems provide durability, energy efficiency, and attractive designs for residential and commercial buildings in the Washington DC area.

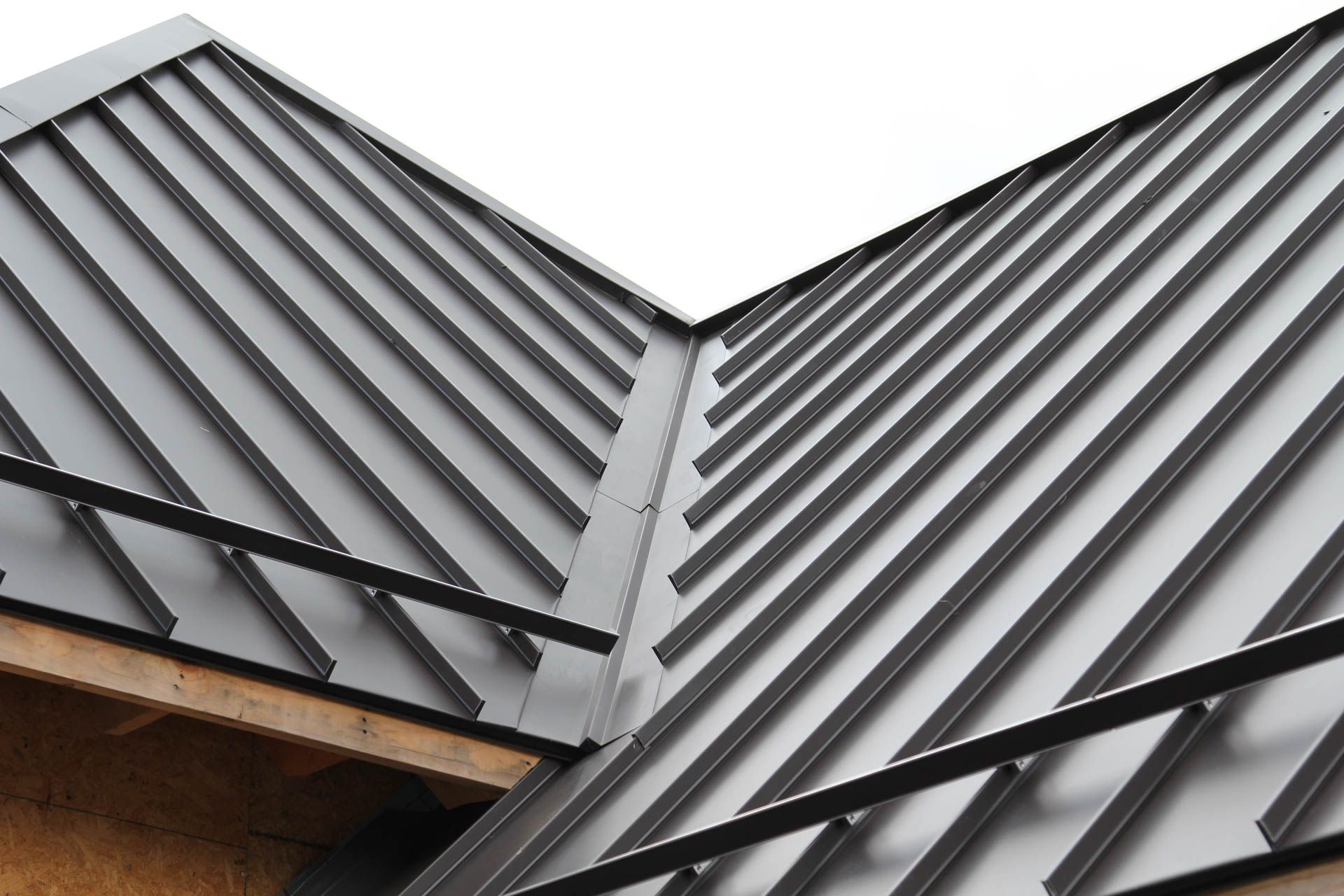

Standing Seam Metal Roofs

Standing seam metal roofs have raised seams that interlock for a sleek, modern look. We install these roofs using high-quality metal panels that can withstand harsh weather conditions. The seams are raised above the roof's surface, allowing water to flow off easily.

These roofs come in various metals like steel, aluminum, and copper. They offer excellent longevity, often lasting 50 years or more with proper maintenance. Standing seam roofs also provide superior energy efficiency by reflecting sunlight and reducing cooling costs.

We can customize the panel width and seam height to match your building's style. Color options range from traditional earth tones to bold, contemporary hues.

Corrugated Metal Panels

Corrugated metal roofing consists of wavy or ribbed panels that add texture and visual interest. We use galvanized steel panels that resist corrosion and stand up to the elements. These lightweight panels are easy to install and transport.

Corrugated roofs offer excellent durability at a lower cost than some other metal options. They can last 40-70 years when properly maintained. The ridges in the panels provide extra strength and help channel water off the roof.

We offer both U-panel and R-panel corrugated styles. U-panels have a rounded, wave-like pattern. R-panels feature a more angular, trapezoidal shape. Both types come in various colors to complement your home's exterior.

Metal Shingles and Slate

Metal shingles mimic the look of traditional roofing materials while providing metal's strength and longevity. We install metal shingles that resemble asphalt, wood shake, or slate roofing. These shingles interlock for a secure fit and excellent weather resistance.

Our metal slate options offer the elegant appearance of natural slate without the weight and fragility. They're made from steel or aluminum with protective coatings. Metal slate resists cracking, fading, and moss growth.

Both metal shingles and slate typically last 30-50 years. They come in a wide array of colors and finishes to match your home's style. These options work well for historic renovations or homes with complex roof designs.

Stone-Coated Steel Tiles

We offer stone-coated steel tiles that combine the strength of metal with the appearance of traditional roofing. These tiles feature a steel base coated with stone granules. The result is a durable roof that looks like clay tile, wood shake, or slate.

Stone-coated steel resists impact damage from hail and falling branches. It also stands up well to high winds. These tiles are lightweight, making them suitable for many existing roof structures without additional support.

The stone coating provides extra noise reduction during rain or hail. It also adds another layer of protection against the elements. We offer various profiles and colors to match different architectural styles throughout Washington DC.

Benefits of Choosing Metal Roofing in Washington DC

Metal roofing offers many advantages for homeowners and businesses in Washington DC. It stands out for its strength, energy savings, eco-friendly nature, and varied looks.

Durability and Longevity

Metal roofs are built to last in DC's climate. They can handle heavy rain, snow, and wind with ease. Most metal roofs last 50 years or more, which is much longer than other types. These roofs don't rot, crack, or need much upkeep. This saves money on repairs over time. Metal also resists fire, which adds safety to your home or building. In DC's hot summers, metal roofs don't warp or damage from the sun's heat. They keep their shape and function for decades.

Energy Efficiency

Metal roofs can cut cooling costs in DC's warm months. They reflect the sun's rays instead of soaking up heat like other materials. This reflection can lower attic temps by up to 30 degrees. Cooler attics mean less work for AC systems and lower bills. In winter, metal roofs can be set up to keep heat in. This helps reduce heating costs when it's cold. Metal roofing from skilled DC installers can boost your home's energy performance year-round.

Sustainability and Eco-Friendliness

Metal roofs are a green choice for DC buildings. They often contain recycled material and can be fully recycled at the end of their life. This reduces waste in landfills. It also cuts down on the need for new raw materials. Their energy-saving qualities also help cut carbon footprints. By using less power for heating and cooling, metal roofs help the environment.

Aesthetic Versatility

Metal roofs come in many styles to fit DC's diverse architecture. From modern to historic, there's a metal roof design for every building. Colors range from bold to subtle. Finishes can be glossy or matte. Textures can mimic other materials like slate or wood. Metal can be shaped into different patterns. This lets it blend with or stand out from other homes on the block.

Metal Roof Repair Services

Metal roofs are durable, but they still need repairs sometimes. We offer expert services to keep your metal roof in top shape. Our team handles leaks, maintenance, and restoration.

Leak Detection and Repair

We find and fix leaks fast. Our skilled technicians use special tools to spot even hidden leaks. We check seams, fasteners, and flashing for problems.

Common leak causes include:

- Loose or damaged fasteners

- Worn sealants

- Gaps in seams

We repair these issues quickly. For small holes, we use sealants or patches. Larger problems may need panel replacement. We match new panels to your existing roof.

Our repairs are long-lasting. We use top-quality materials made for metal roofs. This ensures your roof stays watertight for years to come.

Preventative Maintenance

Regular check-ups keep your roof in great shape. We offer yearly inspections to catch problems early. This saves you money in the long run.

Our maintenance includes:

- Cleaning gutters and drains

- Tightening loose fasteners

- Replacing worn sealants

- Removing debris

We also check for rust and damage from weather or trees. If we find issues, we fix them right away. This stops small problems from getting bigger.

Our team keeps detailed records of your roof's condition. We'll let you know when it's time for more extensive work.

Restoration and Coating

Old metal roofs can often be restored instead of replaced. We offer coating services to extend your roof's life. These coatings reflect heat and stop leaks.

Benefits of roof coatings:

- Lower energy bills

- Increased roof lifespan

- Improved appearance

We clean and prep your roof before applying coatings. This ensures the new layer sticks well. We use high-quality elastomeric coatings that flex with your roof.

For very old roofs, we might suggest partial replacement. We can replace damaged sections while keeping good parts intact. This saves you money compared to a full replacement.

FAQs

Metal roofing in Washington DC comes with unique considerations due to the city's climate and building codes. We address common inquiries about costs, materials, styles, maintenance, and performance.

What factors affect the cost of metal roof installation in Washington DC?

Several elements impact metal roof pricing in DC. The size and pitch of the roof play a big role. Material choice is crucial, with options like steel, aluminum, and copper varying in price. Labor costs can differ based on project complexity.

Accessibility of the building site may affect costs. Permits and inspections required by DC authorities also factor into the total price.

Which metal roofing material offers the longest lifespan for buildings in Washington DC?

Copper metal roofing typically provides the longest lifespan in DC's climate. It can last over 100 years with proper care. Copper develops a protective patina over time, enhancing its durability.

Zinc is another long-lasting option, often reaching 80-100 years. High-quality steel and aluminum roofs can also endure 50-70 years in DC's environment.

Can you outline the main differences between standing seam and corrugated metal roofs?

Standing seam roofs feature vertical panels with concealed fasteners. They offer a sleek, modern look and excellent water shedding. Installation is more complex, resulting in higher costs.

Corrugated metal roofs have a wavy pattern and exposed fasteners. They're more affordable and easier to install. However, they may require more maintenance due to exposed screws.

What maintenance requirements should be considered for metal roofs in Washington DC climate?

Regular inspections are key for metal roofs in DC. We recommend checking for loose fasteners or damaged panels twice a year. Clearing debris from valleys and gutters prevents water buildup.

In winter, safe snow removal may be necessary to prevent ice dams. Repainting might be needed every 20-30 years, depending on the metal type and coating quality.

How does metal roofing performance compare to other materials in extreme weather conditions?

Metal roofs excel in DC's variable climate. They shed snow and rain efficiently, reducing the risk of leaks. High wind resistance makes them suitable for storm seasons.

In summer, metal roofs can reflect solar heat, potentially lowering cooling costs. They're also fire-resistant, providing added safety during dry spells.

Seamless Project Management Process

At Washington Roofing Company, we use a step-by-step approach to manage commercial roofing projects. Our process ensures smooth execution from start to finish.

FAQs

TPO roofing installations come with many common questions from our customers. We've gathered the most important information about costs, durability, brands, and maintenance to help you make informed decisions.

What are the factors influencing the cost of a TPO roof installation?

Several key elements affect TPO roofing costs. The size of your roof is the primary factor, as larger areas require more materials and labor.

The thickness of the TPO membrane impacts pricing significantly. We offer options ranging from 45 mil to 80 mil thickness, with thicker membranes costing more but providing enhanced durability.

Your roof's complexity matters too. Buildings with multiple penetrations, HVAC units, or unusual shapes require more detail work and flashing.

Accessibility affects labor costs. If your roof is difficult to reach or requires special equipment, this will increase the installation price.

How long does a TPO roof typically last under normal weather conditions?

TPO roofs installed by Washington DC Roofing Company typically last 20-30 years with proper maintenance. This lifespan depends on several factors including membrane thickness and local climate conditions.

The quality of installation significantly impacts longevity. Our certified installation team ensures all seams are properly welded and details are correctly finished.

Modern TPO formulations have improved UV and heat resistance compared to earlier generations. This enhancement helps maintain reflectivity and structural integrity over time.

Regular inspections can help identify and address small issues before they compromise the roof's lifespan.

Which TPO roofing brand shows the highest performance and reliability?

We primarily install GAF and Firestone TPO systems due to their consistent performance records and extensive warranties. These manufacturers have refined their formulations over decades.

GAF EverGuard TPO offers excellent heat and UV resistance with their advanced material science. Their products perform exceptionally well in Washington DC's varying climate conditions.

Firestone UltraPly TPO provides superior puncture resistance and flexibility, maintaining performance through seasonal temperature changes. Their seam strength is among the industry's best.

Both brands offer comprehensive warranty options that can extend up to 30 years when installed by certified contractors like us.

Are there any notable drawbacks when using TPO roofing for commercial buildings?

Installation quality is critical with TPO systems. Poorly welded seams can lead to leaks and premature failure, which is why we invest in ongoing training for our installation teams.

Some older TPO formulations had issues with premature aging and cracking. Today's improved materials have largely resolved these concerns, but choosing a quality manufacturer remains important.

TPO can be punctured by sharp objects, making regular roof inspections necessary. We recommend establishing maintenance protocols after installation.

While highly energy efficient, TPO's initial cost may be higher than some traditional roofing systems, though this is typically offset by energy savings over time.

Can a TPO roof be installed over an existing roofing system, and what are the considerations?

Yes, in many cases we can install TPO over existing roofing, potentially saving on removal costs and reducing landfill waste. This approach is called a "recover" installation.

The existing roof must be structurally sound and relatively dry. We conduct moisture scanning to detect any trapped water that could compromise the new system.

Building codes typically limit commercial buildings to two roof layers. We'll verify local regulations and assess your current roofing situation during consultation.

Proper preparation may include adding recovery board insulation to create a smooth, compatible surface for the new TPO membrane attachment.

Tell Us About Your Roofing Project

Contact Us

Our Newsletter

We will get back to you as soon as possible.

Please try again later.

Subscribe For Newsletter

All Rights Reserved | Washington DC Roofing Company